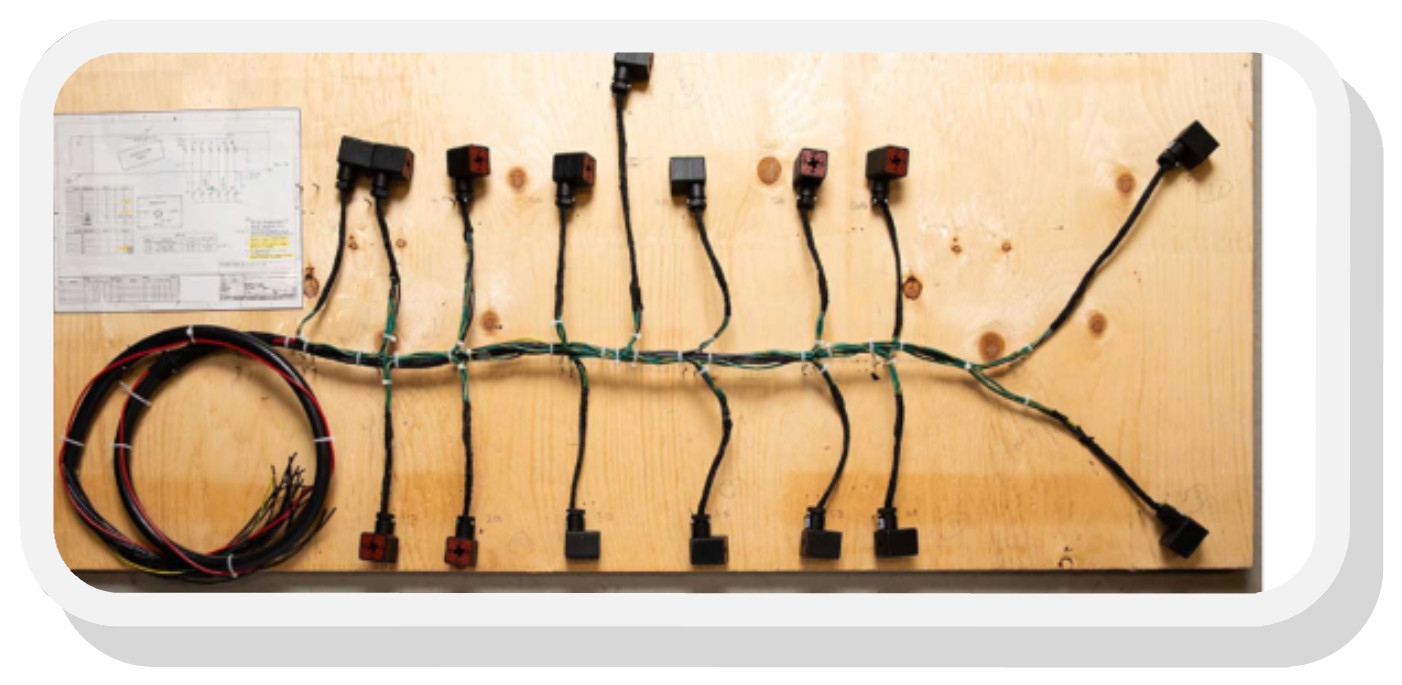

Wiring Harness Assembly

Wiring Harness Assembly

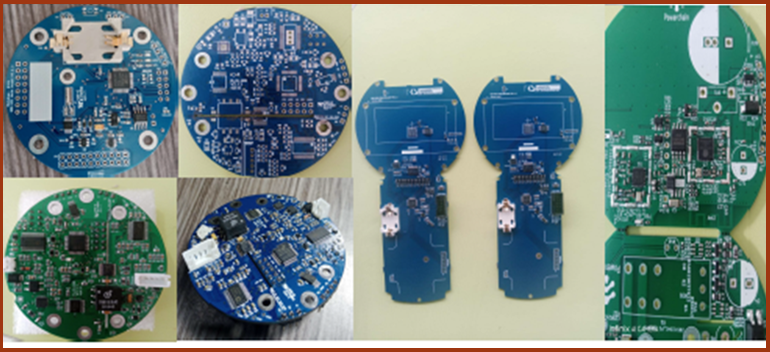

We are a Wire Harness Automotive and Electronic Assembly Specialized Company

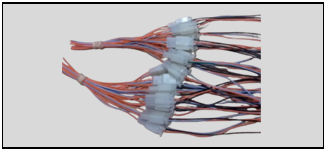

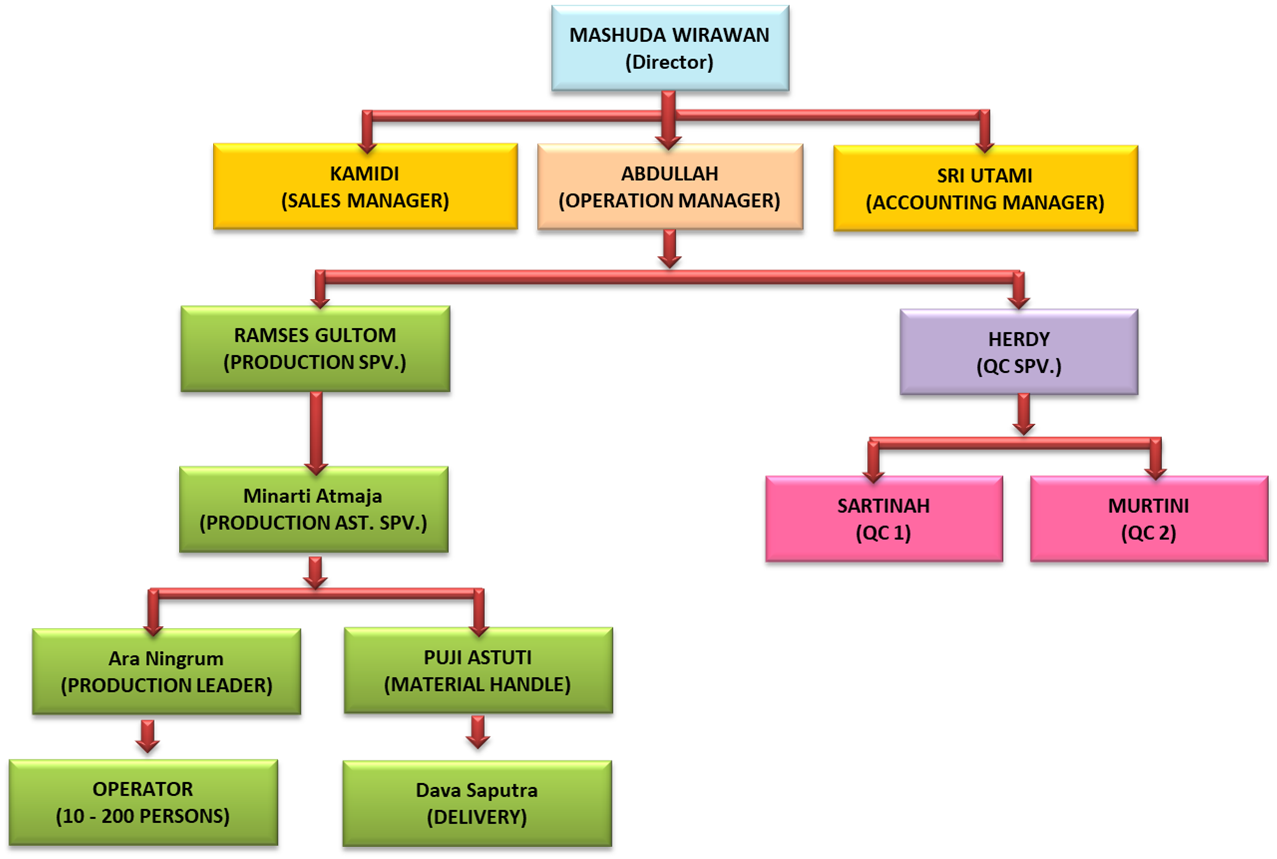

Founded in 2021, PT Sami Jaya Bhakti is a professional Company specializing in the production of wire harness processing and Manual Assembly. Beginning from the Home Industry of Wire Harness Manual Assembly, we give our strong support to all of our customers. Quality insurance and balancing of input and output material are our guaranty for our customer satisfaction.

Quality and Material Control will not provided without professional and experiences man power. With more than 10 years experiences in Wire Harness Assembly we are able to fulfill customer expectation.

Competitive price is one of our service to all of our value customer. Welcome and joint us to become our valuable customer and taste our strong support and service.

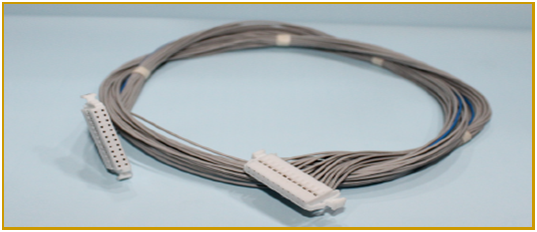

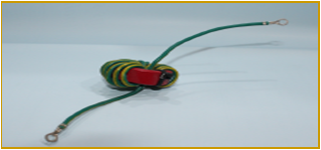

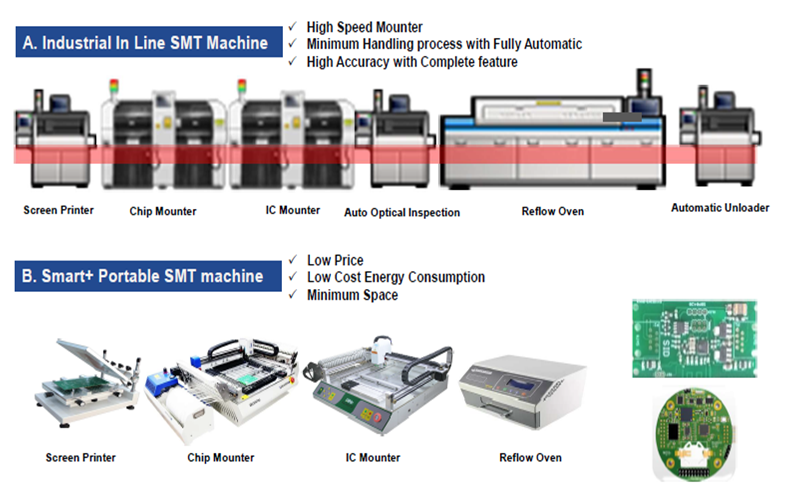

For producing harnesses, we do all the work for production consistently. Taking state-of-the-art technology, we have a strong system for diversified computerization to be able to flexibly deal with. Having the advantage of manufacturing abroad, we can provide a friendly cost to customers in accordance with the changes in times. Not only “lower cost”, but also “high quality” and “reliable delivery date” are provided.

We set a production schedule and procure parts adjusting the delivery date.

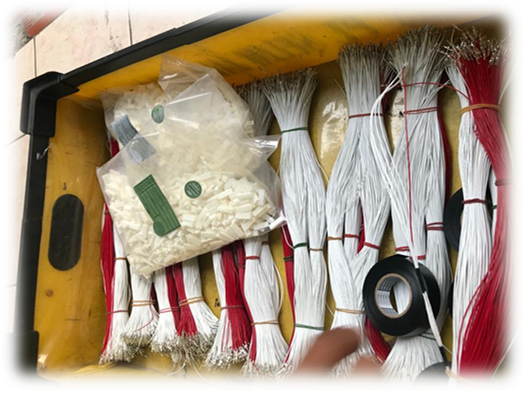

We have appropriate stocks taking into account quick deliveries.

Controlled material stock to avoid production stop due to material shortage.

We put the all information about drawing data from customers into our own system and we make up an estimate based on drawings and the data from the system.

With simplicity of place, we present quality production to our customers

It doesn't have to be expensive to achieve work professionalism

We are quality conscious, because our quality assurance will make us a big company

Quality responsibility is a guarantee for our customer satisfaction

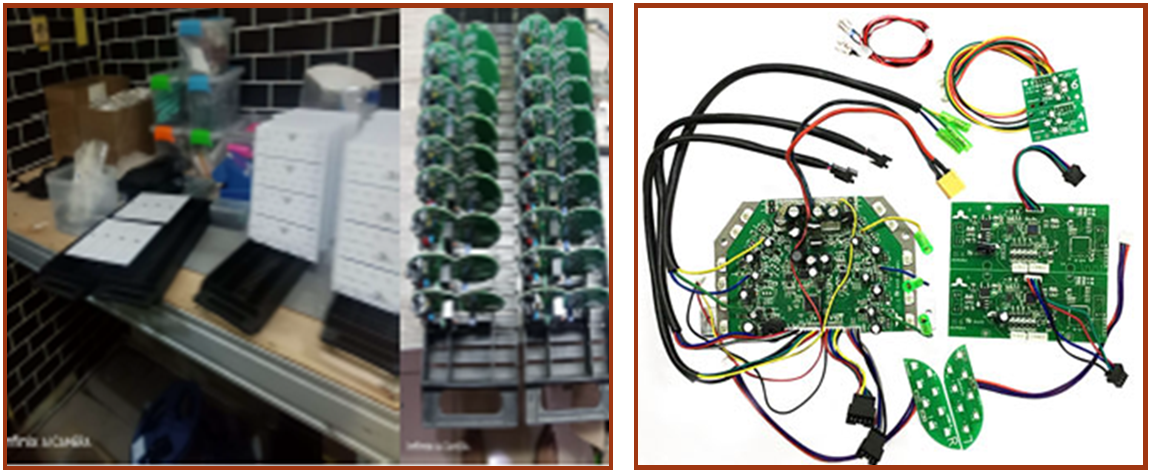

We check size, exteriors, and attached components by visual inspection how it follow the instruction.

The On-time delivery performance refers to the ratio of customer order lines shipped on or before the requested delivery date / customer promised date versus the total number of order lines. This is usually expressed as a percentage and with our experiences, It can be calculated for several measurement periods.

Before producing our intricate and comprehensive designs, We produces first-off prototypes for all our Wire Harness project. This prototype process affords us the opportunity to perfect the assembly and ensure that all components of each Wire project are in line with optimal performance and quality expectation.

Our prototype process includes an extensive quality inspection and sign off before being sent to the customer for inspection. When the client receives their Wire Harnessing prototype, they are free to conduct a detailed inspection that may include modifications and improvement before signing off on the final design.